So this is the current state of the CNC-machine:

|

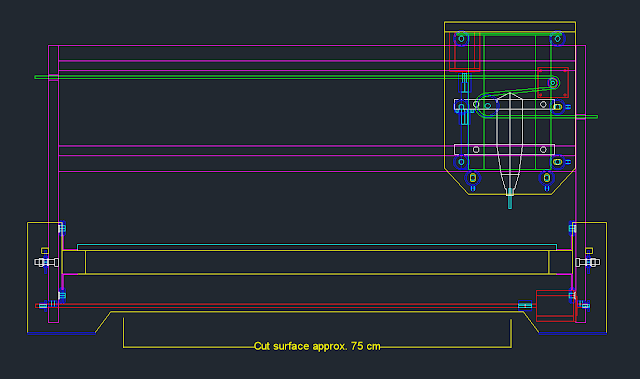

1) Front view. I won't go into a lot of details yet, but it will be chain driven X/Y-wise and a lead screw for the Z-axis.

I hope to reduce the carriage width by around 5-10 cm in the final version. |

|

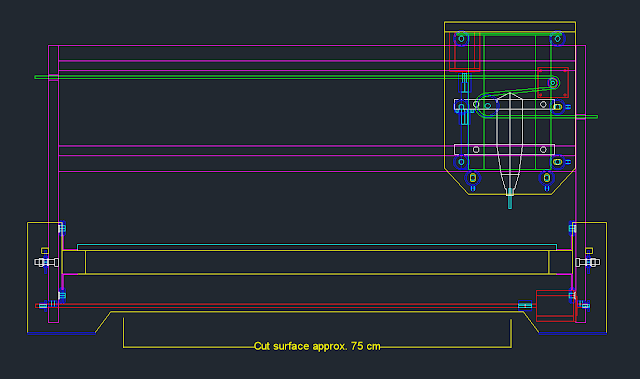

| 2) Side view. Hopefully I've gotten most of the weight centered to avoid wobbling. The expected cut length is around 117.5 cm, which is slightly larger than a regular pinball playfield. Larger pieces can be cut with a little manual repositioning of the carriage and resetting of the zero-position in software, but I do believe this should be sufficient to start with. |

Not too impressive, but I'd rather have it as good as possible before actually making it.

Note that the rails for this design is based on 30mm width/height, but hopefully I'll find L-profiles of a smaller size so the overall design will be slimmer and the cut area slightly larger.

Thoughts?

are you going to use something like tslot for the gantry?

ReplyDeleteMaybe in a future version, they're expensive as ... well - super expensive. ;)

ReplyDeleteThis version will use aluminum L-profiles on which V-groove bearings will run.

Overall - the very first draft/prototype will be made out of MDF boards and cheap L-profiles to keep the costs down. I've spent most of my budget for this project on the V-groove bearings already...Man, they're expensive!

Once everything is running I can think about doing another machine, but I'll most probably finish the pinball before starting another CNC. :)

Hey, so I've been poking around this blog for a while and I can finally offer some advice on something. I have a BlackToe v4.0 and a lot of experience milling playfields (about 15 or so so far). I would consider widening your long axis stance and even consider splurging for 80/20. why? racking will be a huge issue and is for me for a couple of reasons: 1) my mill uses vgroove bearings on plywood/MDO planks (zaxis, gantry) and that stuff wiggles loose. 2) the spindle is too far away from the center of the Y gantry simply because of the materials used. Both of those things mean slop and lack of rigidity.

ReplyDeletebut big deal, right? just go slower? you can't. If you don't run the end mills at a fast enough cut rate (depth of cut + IPM) you'll burn out your very expensive bits. Run them too fast (or as fast as they're supposed to run) and you'll have really sloppy cuts.

This is the problem that I have and absolutely hate. I've resigned to just go slow and get 1/10th of the life out of the bits I use.

Thanks for your input! :)

ReplyDeleteI will definitely consider this - I do however count on this to be the first model that will be refined in a (couple?) of versions along the way. I might also go down the aluminum route along with "fixed cog-rails" instead of chains (don't know the word for it).

Hopefully the first version of the CNC will allow me to do further refinements to the design. :)