Still haven't got my opto's to work but at this moment I'll have to live without them. Will need to debug the circuit and possibly rebuild it separately in the future.

Like most of the work on this build it's a bit of "one step forward, two steps back" since I was only going to screw the board to the backing plate. But... I forgot that the backing plate was made out of cheap fiber board so screws won't work - and - of course the cables didn't reach the intended position for the board.

This worked alright, but due to the placement of the intended cut everything turned out a bit crooked. Not that it matters much, since now it's done. But I know my future self will grin at this during any maintenance session, haha...

"Fun fact" - while checking out the playfield, it turns out most of the rubbers have cracked and need replacements. Again. But I guess I kind of was prepared for that and it'll have to wait until the game logic / game rules are completed and the machine is closed up properly.

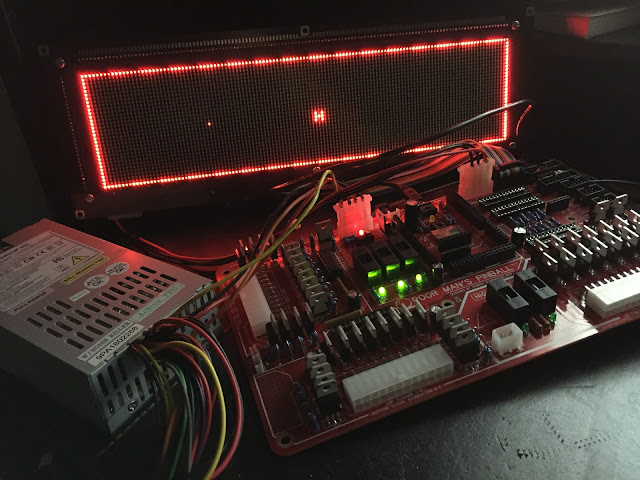

Other than a few mishaps; the board is now installed and I didn't break anything in the process!

|

| Installed and ready to be developed! P.S, ignore the double vision display, there's a small gap between the display and the panel at the moment. |